Introduction

Logo printing refers to printing a company's logo on various products to enhance brand recognition and market promotion. This printing can be applied to different materials and products, such as:

- Clothing: such as T-shirts, caps, etc.

- Stationery: such as notebooks, pens, business cards, etc.

- Packaging: such as paper bags, boxes, etc.

- Advertising materials: such as posters, leaflets, etc.

When undertaking logo printing, the following key considerations typically apply:

- Design quality: Ensure the logo design is clear and professional.

- Printing technology: Select the appropriate printing technique, such as screen printing or digital printing.

- Positioning matching: Ensure the logo's placement aligns precisely with the template's layout.

- Material selection: Choose suitable materials based on the product's intended use.

The Importance of Position Matching in Logo Printing

Position matching in logo printing refers to the precise positioning of logo on products or materials. This aspect is crucial for the following reasons:

- Brand Visibility:

Strategic positioning ensures clear identification at first glance, thereby enhancing brand exposure. - Aesthetic appeal:

Appropriate positioning can enhance aesthetic appeal, such as the symmetry of logo placement and adherence to the designer's original concept. - Professionalism:

Modular design enables templates to closely resemble the final produced items, serving as a benchmark for assessing professional standards. The wrong product may make customers feel that the brand's products are not professional enough.

Logo printing position matching

The core of the logo matching process in this article relies on the template matching. This involves using a predefined template image of the logo and scanning it across the target image to find region where the logo appears. The OpenCV library provides a robust "matchTemplate" function that computes a similarity score across the image, allowing us to pinpoint the location of the logo.

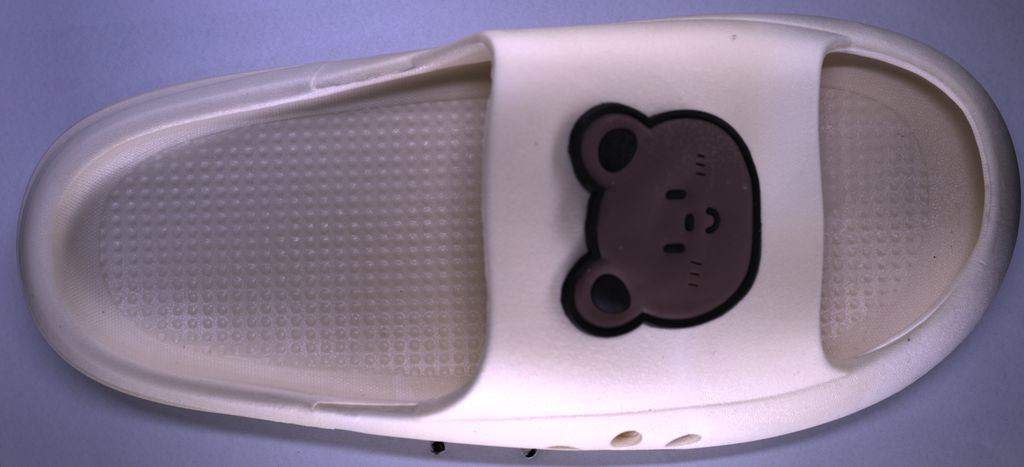

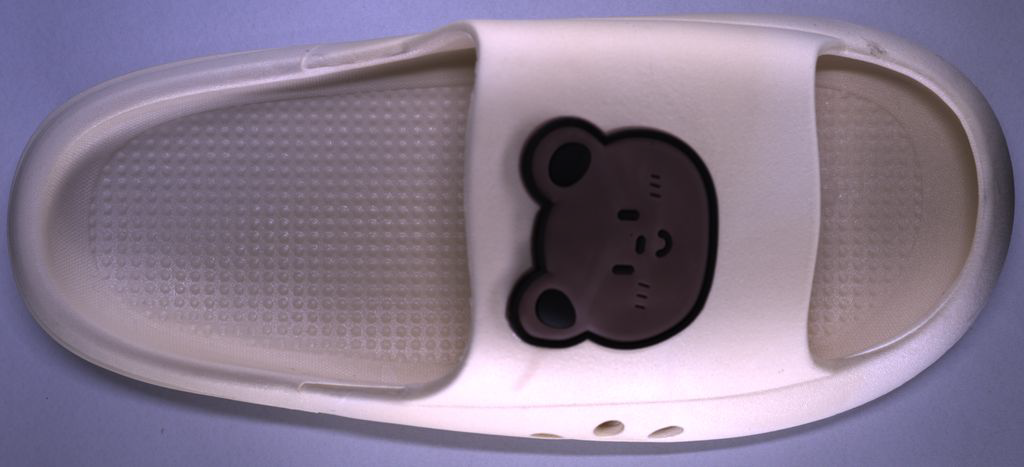

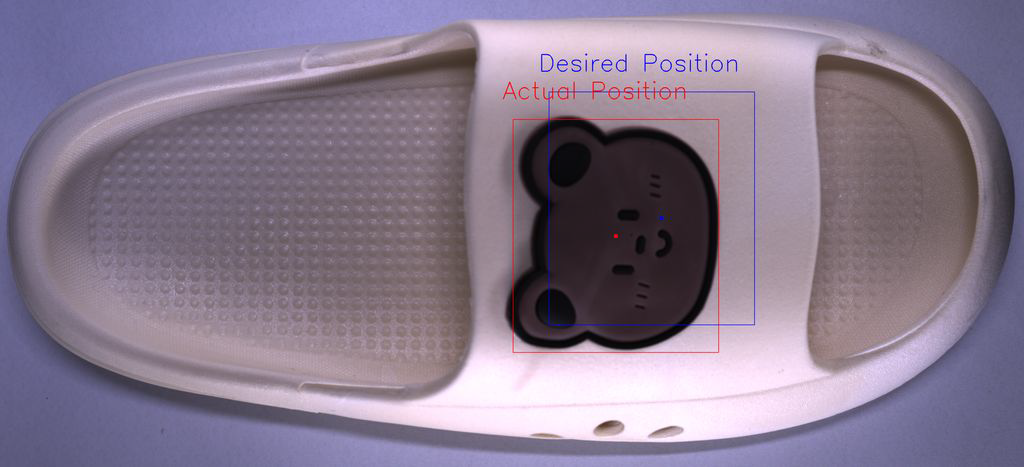

In our approach, we first utilized a perfect sample of the product to establish the desired position of logo within the sample by applying the template matching technique and then determined the actual position of logo within test sample. The offset of the logo in the test sample can be determined by comparing the actual and desired positions of logo. The logo template, a perfect sample with desired position of the logo, a test sample, and the desired and actual location of logo printed on test sample are tabulated below.

logo template | perfect sample | test sample | inference |

|

|

|

|

Our solution enables manufacturers to automate Logo printing position matching, significantly improving accuracy, consistency, and speed compared to manual inspection methods. This substantially reduces costs, minimizes waste, and enhances product quality.

conclusion

For product manufacturing, the optimal outcome is achieving a design that perfectly aligns with the template. For mass-production manufacturers, relying on manual inspection inevitably leads to visual fatigue. However, our solution leverages computer vision technology to automate the logo printing position matching process after training. Compared to traditional methods, this approach significantly enhances company efficiency and improves product quality consistency.

if you want to know more detection of logo printing position matching, please contact info@wisiotech.com for more information!