Industry introduction

The semiconductor industry is a crucial sector that plays a vital role in the development and manufacturing of electronic components and integrated circuits. The industry involves the design, development, and the production of tiny, intricately designed wafers made from semiconductor materials such as silicon.

Industrial problem

In real semiconductor manufacturing scenario, anomalies in the manufacturing processes can occur. Our clients intend to identify uncommon manufacturing defects other than those that are commonly identified.

Our proposed solution

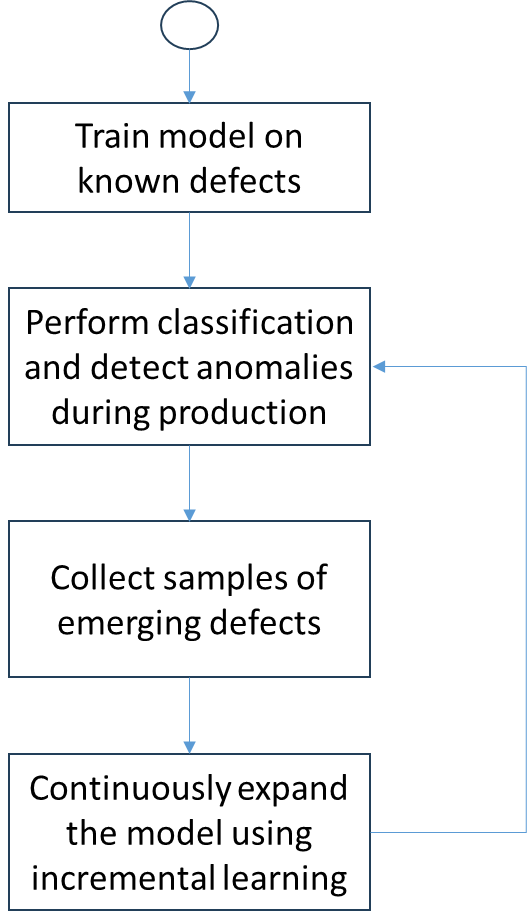

The flowchart of our proposed solution is drawn below, and each block is subsequently explained briefly.

Flowchart of our proposed solution

- Train on known defects

Collect a comprehensive dataset of samples representing the known, commonly identified defect types in the manufacturing process. Train a base classifier model on this known defect data. - Perform classification and detect anomalies during production

Deploy the trained base classifier model on the production line to identify instances of the known defects. Concurrently, monitor the production process for any inputs that the base classifier flags as "unknown" or "anomalous" - these could be potential new, uncommon defects. - Collect samples of emerging defects

Whenever the base classifier detects an anomaly, investigate and collect samples of this new, uncommon defect type. - Continuously expand the OSR Model using incremental learning

Periodically fine-tune or retrain the base classifier model, incorporating the newly collected samples of emerging defects. This allows the OSR model to continuously expand its knowledge and improve its ability to detect both known and previously unseen defect types.

Brief description of our technology edge

Open Set Recognition

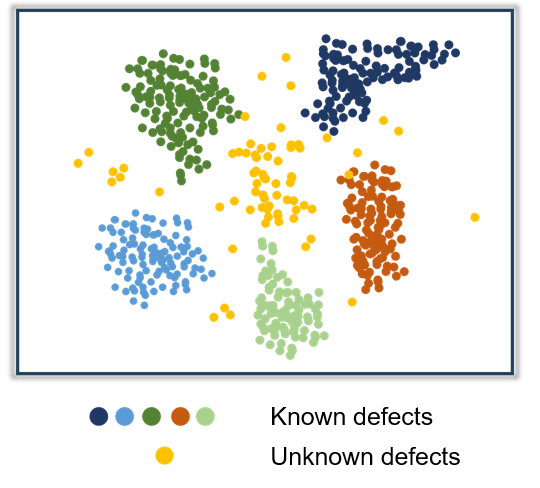

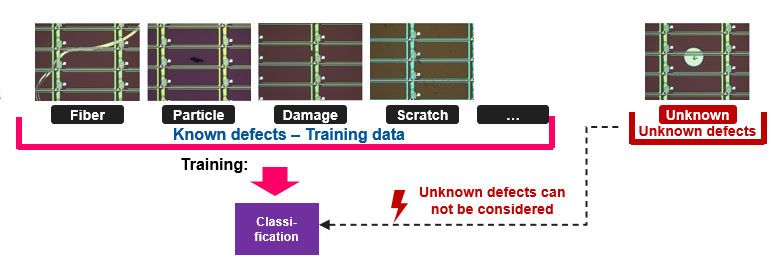

Open Set Recognition (OSR) is a machine learning approach that focuses on handling out-of distribution or unknown samples during model training and deployment. Traditional machine learning models assume that the test data will belong to one of the known classes, but in many real-world scenarios, the data may not necessarily follow this assumption. This is particularly relevant in the semiconductor industry, where manufacturers often encounter anomalies and new types of defects during the production process that were not part of the original training data.

An example of the above description is given below where the classifier is fed with an unknown defective sample image [1].

Incremental Learning

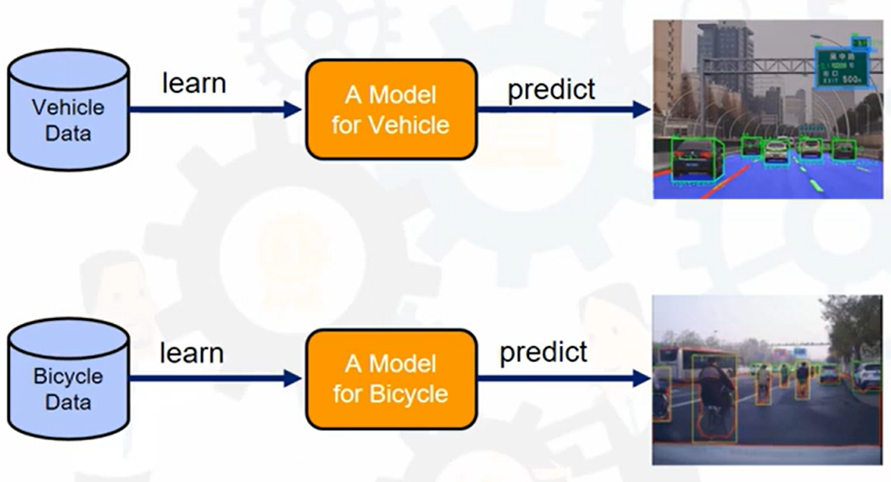

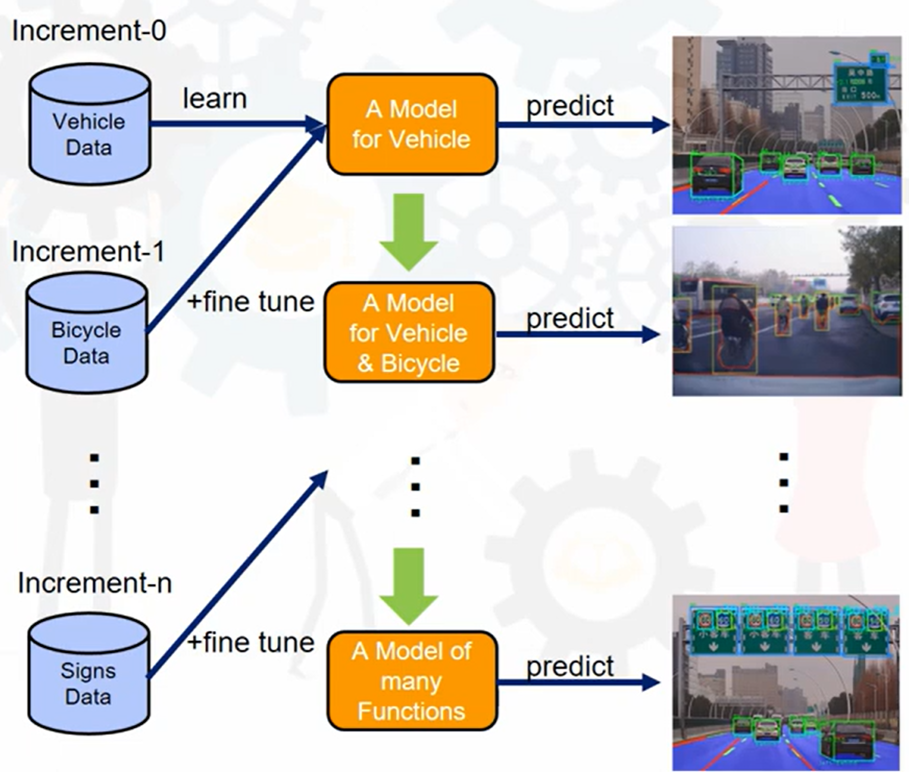

Incremental learning (IL) (also known as continual learning) is a methodology of machine learning where an AI model learns new information over time, maintaining and building upon previous knowledge. An example of object detection in autonomous vehicle driving is shown below. The model for vehicle is first trained to detect cars. Later on, if the same model is trained to detect bicycles, it might lose its previous knowledge to detect cars.

A practical approach would be incremental learning where the model is trained to learn new objects but also retain previously learned knowledge about objects as shown below.

There are three common scenarios of IL - namely, task-IL, domain-IL, and class-IL. A brief description of these three scenarios along with their industrial applications is tabulated as follows:

Scenario | Intuitive description | Semiconductor industry applications |

Task increment ai learning | Sequentially learn to solve a number of distinct tasks | Task IL enables incremental updates to defect detection models for new defect types at different processing steps (each with unique defect types), maintaining ability to detect defects from previous processing steps to improve the versatility of the defect detection system and easy adaptation to different stages of the semiconductor manufacturing process. |

Domain increment ai learning | Learn to solve the same problem in different contexts | Semiconductor industry has a wide range of device types (logic, memory, power, RF) with unique defect characteristics. Domain IL enables incremental updates to defect detection models for new device domains. This helps to avoid retraining the entire model from scratch and facilitates rapid development and adaptation of defect detection systems. |

Class increment al learning | Discriminate between incrementally observed classes | Allows the defect detection and classification models to be updated to recognize new classes of defects that may emerge over time as processes and materials evolve, without forgetting how to detect the previously learned defect types. |

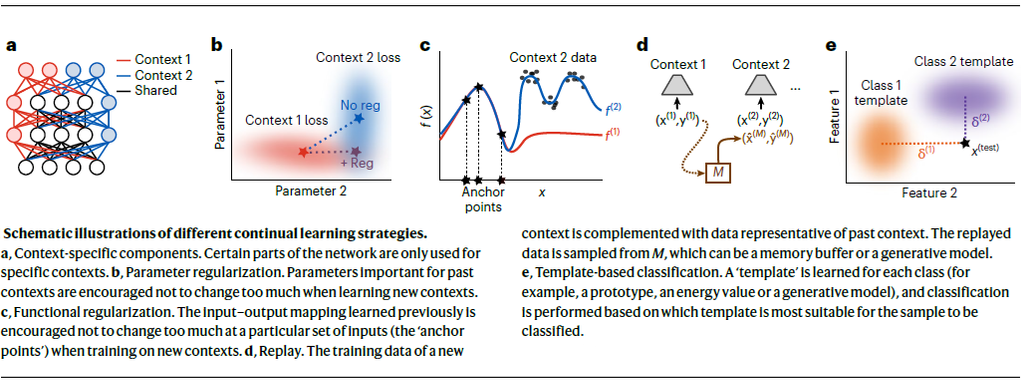

There are various strategies to implement IL including training context-specific components, parameter regularization, functional regularization, replay, and template-based classification. The various strategies can be graphically represented as follows [2]:

The various strategies for implementing IL, such as training context-specific components, parameter regularization, functional regularization, replay, and template-based classification, can be further explored and tailored to the specific requirements of the semiconductor industry.

Conclusion

By harnessing the power of OSR and IL, the proposed solution aims to enhance the versatility, adaptability, and longevity of the defect detection systems in the semiconductor manufacturing domain.

References

[1] S. W. Yang, C. S. Lin, S. K. Lin, and H. T. Chiang, “Automatic defect recognition of TFT array process using gray level co occurrence matrix,” Optik, vol. 125, no. 11, pp. 2671-2676, 2014.

[2] G. M. V. d. Ven, T. Tuytelaars, and A. S. Tolias, “Three types of incremental learning,” Nature Machine Intelligence, vol. 4, no. 12, pp. 1185-97, Dec. 2022.

if you want to know more semiconductor industry, please contact info@wisiotech.com for more information!